Choosing and Using an Ultrasonic Cleaner for Carburetors

In the vast world of automotive mechanics, certain components have stood the test of time, proving their resilience and importance. Among these, the carburetor holds a special place. While modern vehicles have largely shifted to fuel injection systems, the carburetor remains a significant component in many older and classic cars. Its maintenance, particularly cleaning, is crucial for optimal performance. This is where the ultrasonic cleaner comes into play, revolutionizing the way we approach carburetor maintenance.

Ultrasonic cleaners have revolutionized the way we clean intricate items, from delicate jewelry to robust auto parts. Their increasing affordability has made them a popular choice for both professionals and hobbyists. However, as with any tool, knowing how to use it effectively can make all the difference.

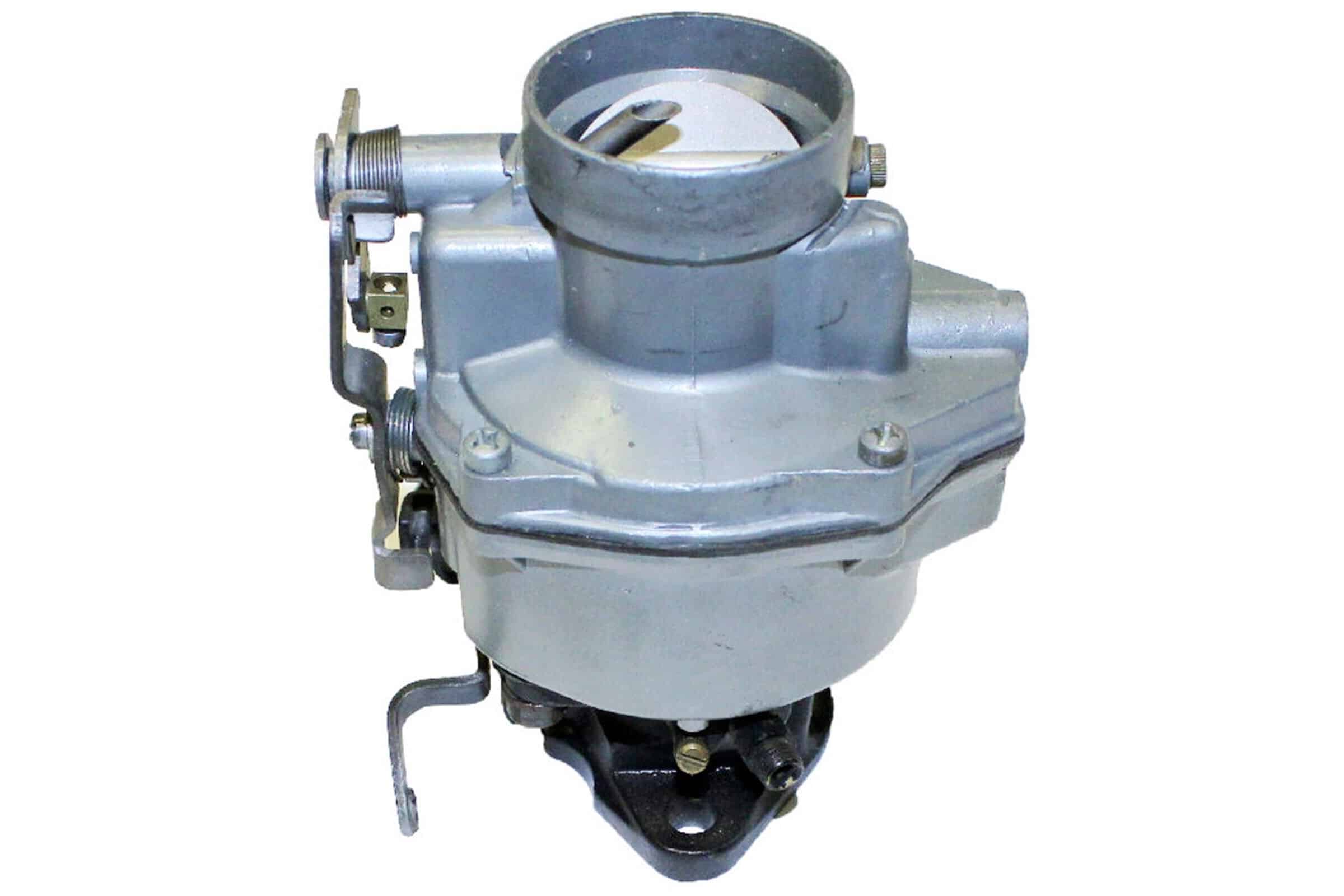

Understanding the Carburetor’s Role

Before diving into the cleaning process, it’s essential to understand the carburetor’s function. Acting as a bridge between the fuel system and the engine, the carburetor’s primary role is to mix air and fuel in the right proportion to ensure efficient combustion. Over time, residues like carbon deposits, dirt, and other contaminants can accumulate, affecting the carburetor’s performance. This makes regular cleaning not just recommended but necessary.

The Rise of Ultrasonic Cleaning in the Automotive World

Ultrasonic cleaners have emerged as a beacon of hope in the automotive maintenance realm. These devices, which might seem futuristic to some, harness the power of high-frequency sound waves to create a cleaning process that’s both thorough and gentle.

When these sound waves travel through an ultrasonic cleaning solution, they produce microscopic bubbles. These bubbles grow until they can no longer sustain their size, at which point they collapse or “implode.” This implosion releases a significant amount of energy, resulting in a scrubbing action that effectively removes contaminants from the parts submerged in the solution.

For carburetors, this means:

Deep Cleaning: Every nook, cranny, and hidden corner of the carburetor gets cleaned, ensuring optimal performance.

Safety: The cleaning process is gentle, reducing the risk of damaging delicate parts.

Efficiency: Cleaning that once took hours can now be completed in a fraction of the time.

Environmental Considerations: With a shift towards eco-friendly practices, ultrasonic cleaners, which use biodegradable solutions, are a step in the right direction.

The Traditional vs. Ultrasonic Cleaning Debate

Traditionally, cleaning carburetors involved manual scrubbing, using solvents, brushes, and a lot of elbow grease. Not only was this process time-consuming, but it also posed risks. Harsh chemicals could damage parts, and there was always the chance that some contaminants would remain, hidden in parts of the carburetor that brushes couldn’t reach.

Ultrasonic cleaning changes this narrative. The cleaning process is consistent, reaching even the most challenging parts of the carburetor. The use of biodegradable solutions also means a reduced environmental footprint, making it a win-win.

Step-by-Step Guide to Using an Ultrasonic Cleaner for Carburetors

- Selection of Cleaning Solution: Depending on the contaminants, choose a biodegradable ultrasonic cleaning solution. Some solutions are designed to tackle grease, while others might be better suited for carbon deposits.

- Preparing the Cleaner: Begin by filling the ultrasonic cleaner tank with water. Add the chosen cleaning solution, ensuring you follow the manufacturer’s recommended proportions. Activate the unit, allowing it to run for about 10 minutes. This step, known as degassing, ensures optimal performance by removing trapped air from the solution.

- The Cleaning Process: Place the disassembled carburetor parts into the cleaner’s mesh basket. This prevents them from touching the tank’s bottom, which can affect the cleaning process. Submerge the basket in the cleaning solution, set the timer (typically 20 minutes, but this can vary), and start the cleaning process.

- Post-Cleaning Steps: Once the cycle is complete, remove the parts from the solution. Rinse them with fresh water to eliminate any residual cleaning solution. It’s crucial to dry the parts thoroughly before reassembling the carburetor to prevent any potential issues.

The Long-Term Benefits of Ultrasonic Cleaning

While the immediate results of ultrasonic cleaning are evident in the form of a sparkling clean carburetor, the long-term benefits are equally significant:

Extended Carburetor Life: Regular and thorough cleaning can extend the carburetor’s lifespan, ensuring you get the most out of your investment.

Improved Vehicle Performance: A clean carburetor functions optimally, leading to better vehicle performance, improved fuel efficiency, and reduced emissions.

Cost Savings: With the carburetor functioning at its best, there’s a reduced need for frequent repairs and replacements, leading to cost savings in the long run.

FAQs

An ultrasonic cleaner is a device that uses high-frequency sound waves to produce microscopic bubbles in a cleaning solution, which effectively removes contaminants from objects submerged in the solution.

Ultrasonic cleaning works through a process called cavitation. High-frequency sound waves produce tiny bubbles that expand and collapse rapidly, releasing energy that creates a scrubbing action on the object’s surface.

Ultrasonic cleaning is thorough, efficient, and gentle, making it ideal for cleaning intricate parts of carburetors without causing damage.

The frequency depends on the vehicle’s usage and the environment. However, for optimal performance, cleaning every six months to a year is recommended.

No, ultrasonic cleaning is gentle and won’t damage your carburetor. However, always ensure you use the recommended cleaning solution and follow the manufacturer’s guidelines.

It’s best to use a biodegradable ultrasonic cleaning solution formulated for carburetors. The specific solution might vary based on the contaminants you’re trying to remove.

Typically, a cleaning cycle lasts about 20 minutes, but this can vary based on the cleaner’s model and the level of contamination.

Yes, especially when using biodegradable cleaning solutions. It reduces the need for harsh chemicals, making it an eco-friendly choice.

Absolutely! Ultrasonic cleaners are versatile and can be used to clean various automotive parts, including screws, bolts, and other smaller components.

Partial disassembly is recommended to ensure the cleaning solution reaches all parts of the carburetor.

Traditional cleaning often involves manual scrubbing with solvents and brushes, while ultrasonic cleaning uses sound waves to achieve a deep and thorough clean

Yes, ultrasonic cleaning is gentle on aluminum parts, reducing the risk of future corrosion.

Symptoms like reduced engine performance, poor fuel efficiency, or difficulty starting the vehicle can indicate a dirty carburetor.

While water can be used, adding a cleaning solution enhances the cleaning effectiveness.

Regularly clean the tank, replace the cleaning solution after several uses, and ensure the device is stored in a dry place.

While ultrasonic cleaners are versatile, avoid cleaning items with loose parts or those that might be sensitive to water and cleaning solutions.

Ultrasonic cleaners operate at high frequencies, often beyond human hearing range. However, some models might produce a soft humming sound.

Degassing removes trapped air from the cleaning solution, ensuring optimal cleaning performance.